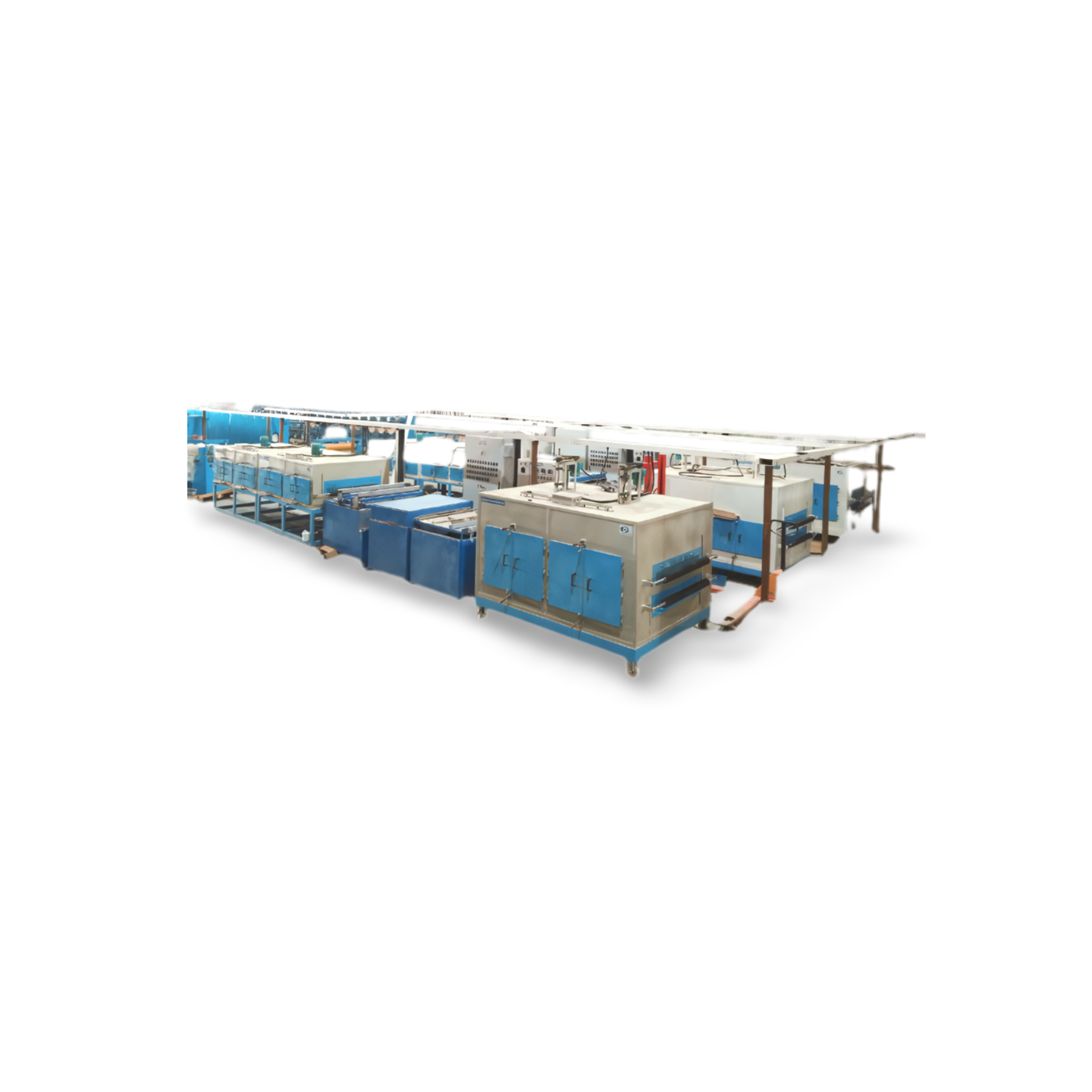

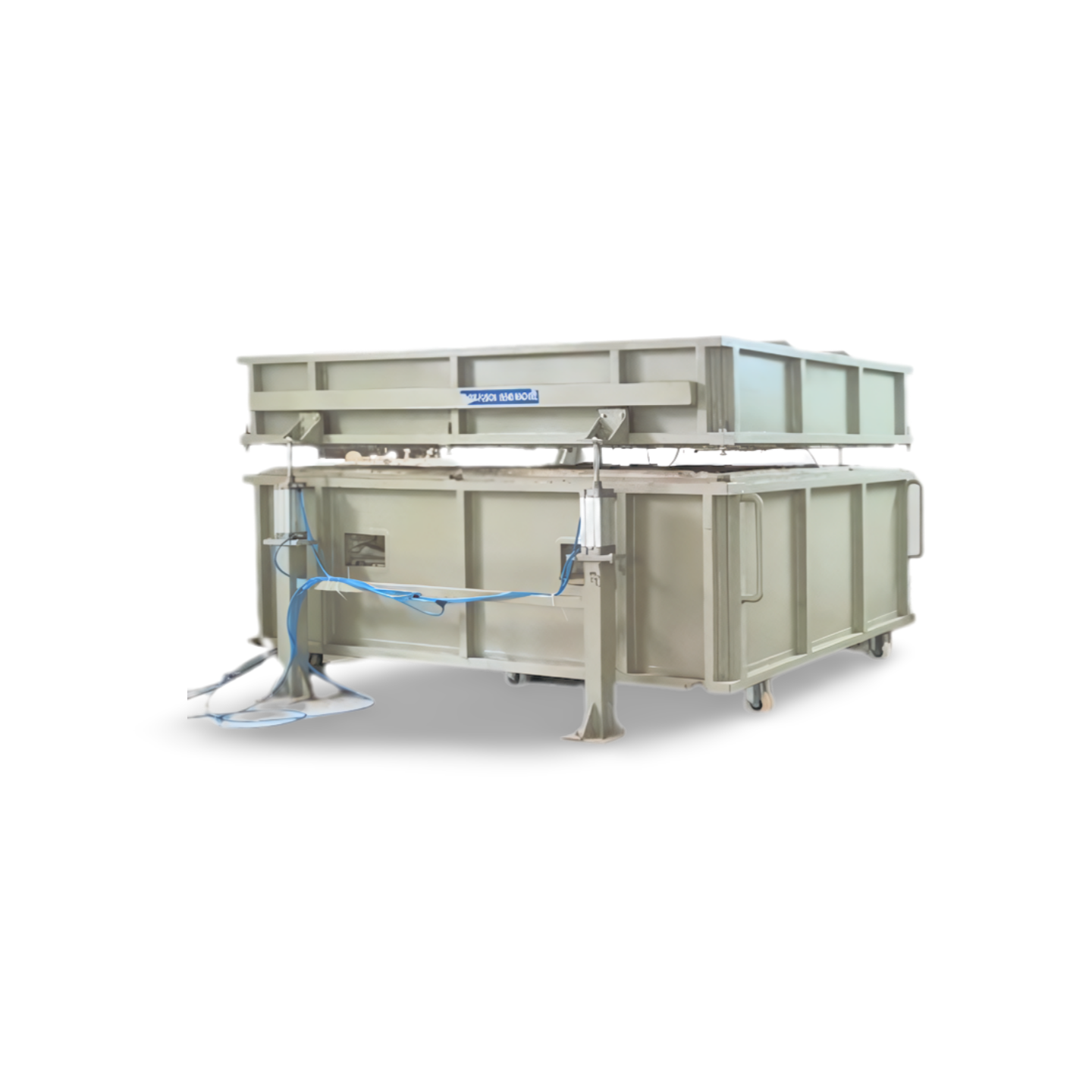

MATERIAL HANDLING SYSTEM

Material Handling Equipment’s is backbone for any process industry for long process

and effective floor utilization. We offer multiple type of material handling equipment’s as per

specific material handling requirement considering product geometry, bulk density and chemical

properties.

Basic function of Material handling equipment’s is to reduce human efforts and

synchronize with automation as per production requirement.

Basic function of Material

handling equipment’s is to reduce human efforts and synchronize with automation as per

production requirement.